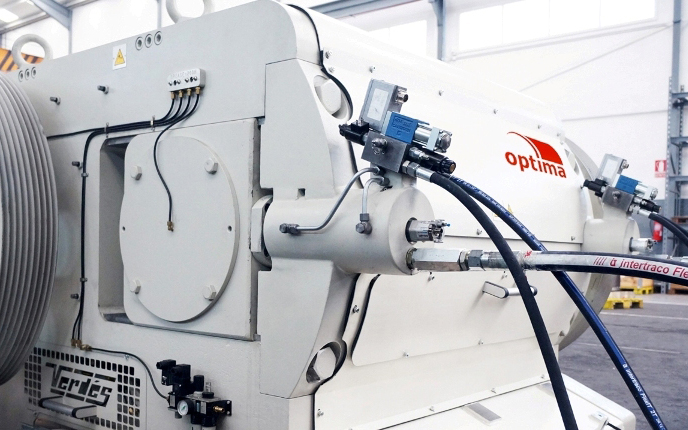

Optima Roller Mills

Course Details

Optima Roller Mills are commonly used for efficient clay and mineral grinding and crushing. They have been designed to provide high performances, working with total reliability thanks to a new design with a robust, oversized bedplate as well as high precision and high load capacity bearings. The pressure between rollers is in all cases hydraulic in the entire Optima Roller Mills range. One of its outstanding features is the innovative separation system between rollers of the H and R models, providing the desired gap with a precision of less than 0.01 mm. Optima Roller Mills come in versions from 600 to 1400 mm in width with tangential speeds of up to 21 m/s.

Key Factors:

- Simple and compact design

- Robust vibration-free bedplate with minimum deformation

- High wear resistant roller shells

- Maximum roller gap precision

- High working pressure to guarantee the particle size