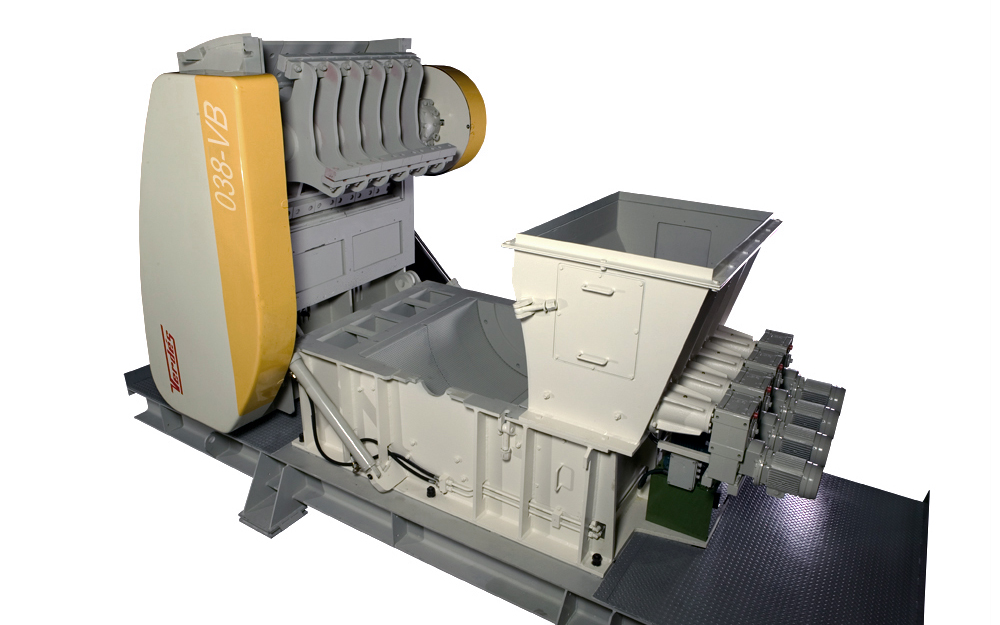

Hammer Mills

Course Details

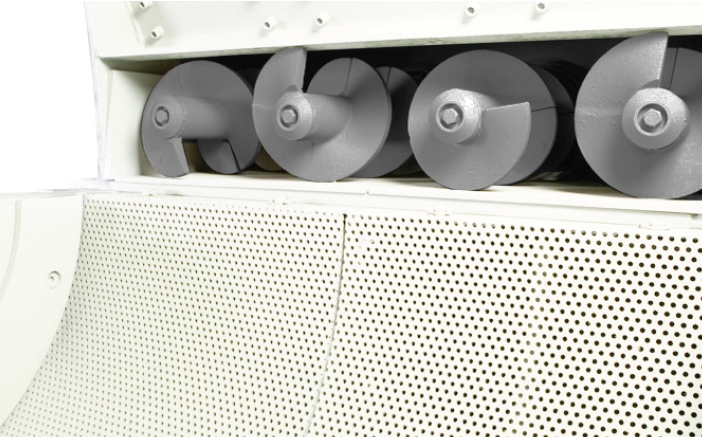

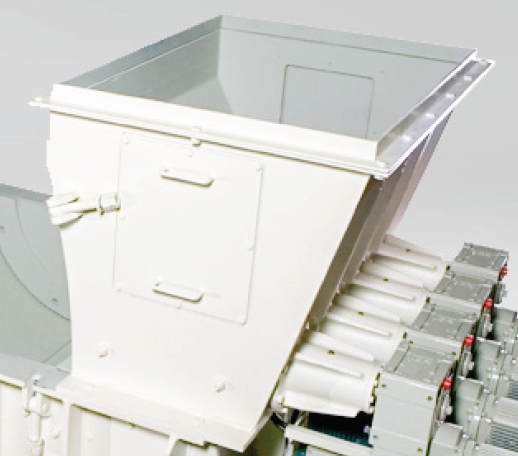

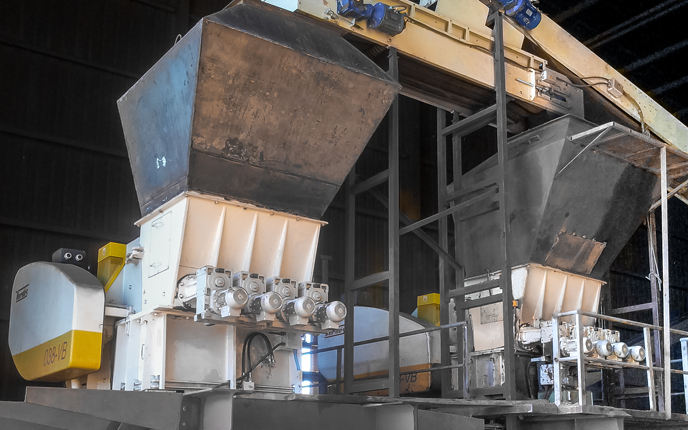

Their versatility makes them suitable for grinding non-ferrous materials. They are essential in dry-process lines and particularly suitable for grinding clay intended for the manufacture of high-added-value ceramic products. They achieve a high degree of milling capacity, with a high percentage of fines under 500 micron and optimal granulometric curves for the manufacture of ceramic products. They have been specially designed to facilitate visual inspection and quick access for maintenance that can be performed by a single operator without auxiliary mechanical means. These mills are available in a wide range of sizes and configurations, ensuring excellent flexibility and adaptation to different raw materials and working conditions, reaching production rates up to 100 t/h.

Key Factors:

- Excellent accessibility

- Eregonomic design

- Flexible operation

- Quick and easy maintenance

- High production capacity

- Maximum adaptability

- Minimum dust emissions

Hammer Mills on pictures: